CHOOSE US

Quality is the core productivity

In the management of the implementation of the "brand" strategy, strict process selection, scientific and rigorous production, products, services, brands continue to carry out regular quantitative evaluation and improvement, to provide customers with satisfactory service quality, is our eternal commitment!

ABOUT DINGSHENG

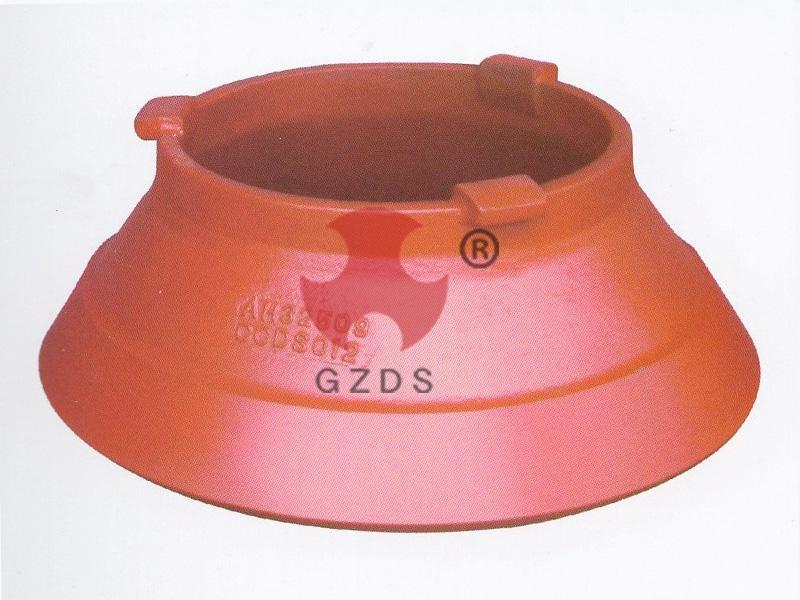

GZDS

ALWAYS PUT QUALITY FIRST, IMPLEMENT EVERY DETAIL

The company has exquisite technology and complete testing methods. It has advanced production equipment such as intermediate frequency induction melting furnace, automatic heat treatment furnace, sand processing machine, and complete modern analytical instruments such as spectrochemical composition analysis, metallographic organization analysis, and mechanical performance testing; The company has dozens of engineers and technicians specializing in medium and advanced casting, wear-resistant materials, and heat treatment, with independent research and development capabilities for new technologies and new processes; at the same time, it has cooperated with many domestic universities and scientific research institutes to develop projects, and hired many well-known domestic wear-resistant material experts and scholars to form an expert think tank, so that the company's production and scientific research have a reliable technical guarantee.

The company was established in

Company Scale (㎡)

Cooperation Customers

Honor (item)

NEWS

News

Pay attention to us and keep abreast of company dynamics

Current Status and Level of Forging Development in China

In recent years, China's forging technology has made a lot of achievements, new materials, new technology, electronic technology, computer technology, high-precision processing technology, measurement technology, heating and cooling technology, automation technology and other aspects have been greatly improved, but there is still a big gap compared with developed countries.

Casting-precision casting-sand casting-casting related knowledge to explain

Wide range of adaptation. The casting method is almost not limited by the size, thickness and shape complexity of the casting. The wall thickness of the casting can reach 0.3~1000mm, the length is from a few millimeters to more than ten meters, and the quality is from a few grams to more than 300t. It is suitable for producing parts with complex shapes, especially complex inner cavities, such as complex boxes, valve bodies, impellers, engine cylinders, propellers, etc.

2024-04-29

Current Status and Level of Forging Development in China

In recent years, China's forging technology has made a lot of achievements, new materials, new technology, electronic technology, computer technology, high-precision processing technology, measurement technology, heating and cooling technology, automation technology and other aspects have been greatly improved, but there is still a big gap compared with developed countries.

2024-04-29

Casting-precision casting-sand casting-casting related knowledge to explain

Wide range of adaptation. The casting method is almost not limited by the size, thickness and shape complexity of the casting. The wall thickness of the casting can reach 0.3~1000mm, the length is from a few millimeters to more than ten meters, and the quality is from a few grams to more than 300t. It is suitable for producing parts with complex shapes, especially complex inner cavities, such as complex boxes, valve bodies, impellers, engine cylinders, propellers, etc.